Imitation-wood polymer material

It is a two components polyurethane resin moulded under pressure in hydraulic presses. This type of foaming polyurethane rated density is of 20-lb/cu ft (320 kg/cu m). Developed to produce decorative mouldings, architecture elements, frames and other similar applications.

Quality of the manufacturing

In order to guaranty the best quality, these pieces are to be manufactured according to precise Iso standards: mixing ratio; temperatures and duration of stages such as creaming, gel, rising and resting.

.

These Iso standards are clear and precise to reach the required densities. (Ref: BASF Technical Reference Elastopor R2577(Réf :

BASF Technical Reference Elastopor R2577)

Note :

Some manufacturers try to avoid these standards to speed up their production levels and to reduce their manufacturing costs. This leads to bending, "straw" densities, and doubtful finish quality and contraction/expansion effects that may cause serious joints problems.

History:

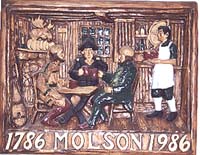

This type of material was used for the first time 25 to 30 years ago. It was used to reproduce craftsmen’s sculptures, commemoratives plates (Photo Molson 1786-1986), furniture pieces for cabinetmakers, mirror frames and others, as well as scale-models and windows shops mannequins.

This type of material was used for the first time 25 to 30 years ago. It was used to reproduce craftsmen’s sculptures, commemoratives plates (Photo Molson 1786-1986), furniture pieces for cabinetmakers, mirror frames and others, as well as scale-models and windows shops mannequins.

You know this kind of product since long ago and you have it home without knowing! Bed head pieces; dressers; kitchen chairs, frames, etc…